Originally Posted January 8th, 2026

R710 Roof Bolter

The R710 Battery Powered Roof Bolter has been in regular use underground since late August 2025. Operators regularly install upwards of 100 bolts on single charge, with the option to connect the R710’s tethered 600-volt power module for larger-scale installation.

Why is Our Roof Bolter Better?

The R710 Roof Bolter provides the same roof support at traditional diesel-powered bolters while offering several key advantages.

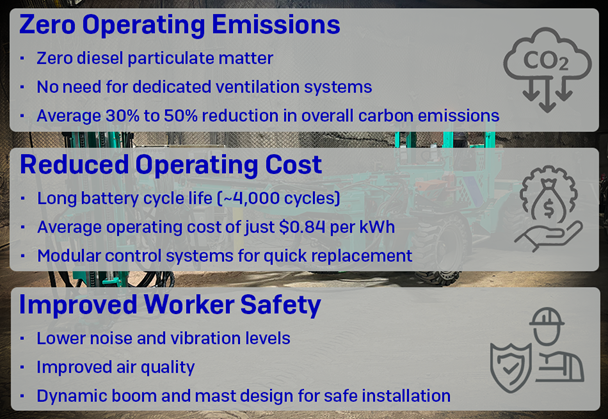

Battery powered units produce zero operating emissions.The R710 doesn’t emit any diesel particulate matter. This means that the mine doesn’t have to purchase any additional dedicated ventilation system to account for the unit’s emissions. A fleet of battery powered equipment typically results in a 30% to 50% reduction in a mine’s overall carbon emissions.

Battery powered units cost less to operate than their diesel counterparts. Current Rokion battery cells have an average lifespan of 4,000 cycles and an average operating cost of just $0.84 per kilowatt-hour. The R710’s modular control systems allow service personnel to quickly swap out components, reducing equipment downtime.

Battery powered units offer a safer working environment for operators. Compared to diesel roof bolters, the R710 produces considerably less noise, vibration, and heat. The R710’s indexing boom and mast allows the operator to drill and bolt under an unsupported roof while keeping themselves at a safe distance.

Rokion is currently developing a remote-operated R710 configuration with a shorter cab for use in mines with low roof heights or unstable environmental conditions.

We calculate our average usage, operating cost, and battery life using the R710’s onboard data logger. These loggers collect information on the state of the battery modules, motors, power management systems, and communication systems. Our service and engineering teams use this data during machine repair and troubleshooting, and during equipment design and improvement.

Built On A Strong Foundation

The R710 boom and mast designs are based on those featured on the Prairie Machine Xcel Roof Bolter series. The extendible boom design allows an operator to drill and bolt from as far as twenty feet away, ensuring personnel do not have to work underneath an unsupported roof. The indexing mast can tilt as much as 72° and rotates up to 90° in either direction so that operators can install roof supports effectively throughout the mine.

With demand for battery electric equipment continuing to grow, the push to produce safe, reliable electric mining equipment is stronger than ever. The R710 Roof Bolter provides a safe working environment for mine staff and offers exceptional roof support at a fraction of the cost of its diesel counterparts.