Posted March 8th, 2024

CATL Battery Cells

As electric vehicles continue to grow in popularity, manufacturers strive to provide better products. This includes extending the vehicle’s travel range, increasing payload, and supplying quicker charging time. While all important for day-to-day use, the vehicle’s battery service life is the most important factor for prospective drivers.

Battery Module Service Life

An electric vehicle battery module reaches its end of service when its capacity lowers by 20 to 30%. From this point, each charge-discharge-charge cycle lowers battery capacity even further. And the pack will no longer be suitable for powering the vehicle.

The operating temperature during charging is a key factor in how soon a battery reaches end of its service life.

At a 25° Celsius average charging temperature, a lithium-ion battery module can expect to complete over 2,000 charge cycles before its capacity diminishes. Conversely, at 45° Celsius, that same battery module may only reach 500 charge cycles before it approaches the end of service life.

Given the extreme temperatures of underground hard and soft rock mines, Rokion has been hard at work designing methods to improve the service life of their battery modules.

CATL Cell Battery Modules

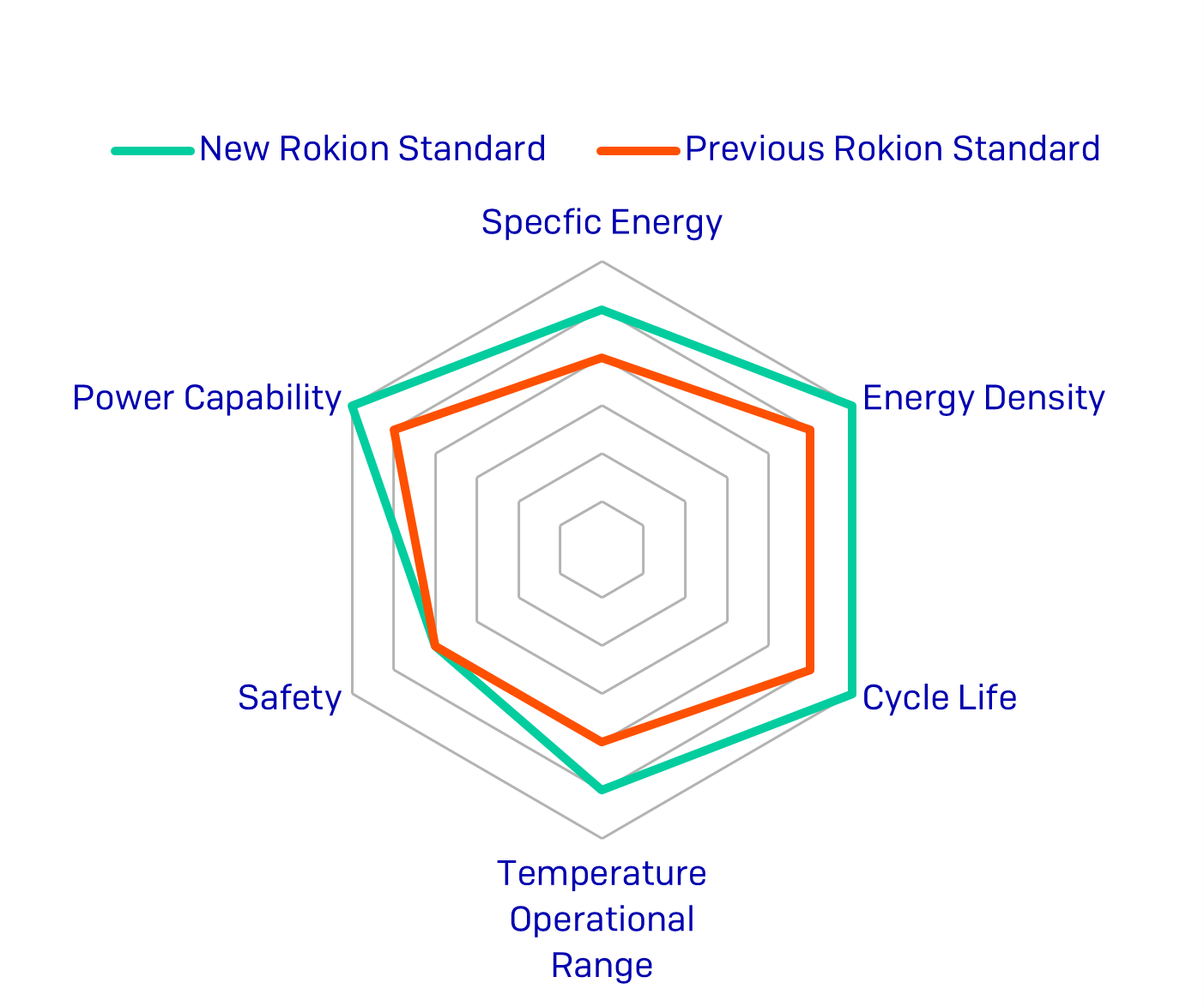

After considerable research into battery cell types, characteristics, and compositions, Rokion found that CATL battery cells were best suited for underground mining trucks. CATL battery modules are made up of several sub-modules, the number of which varies based on vehicle type, and offer several advantages over previous configurations:

During extensive on-site charge/discharge testing, Rokion observed that the CATL cell battery modules had an average cycle life three times greater than previous configurations. Like previous Rokion battery module configurations, CATL cell battery modules feature Lithium Iron Phosphate (LiFePO4) composition, offering excellent performance and high chemical and thermal stability.

Conclusion

Rokion has already begun manufacturing R200 battery powered electric trucks with the CATL battery module configuration. We look forward to integrating this latest battery technology into the R100, R400, and R700 platforms, both in new builds and in battery module rebuilds.