Posted March 8th, 2022

WHAT IS REGENERATIVE BRAKING?

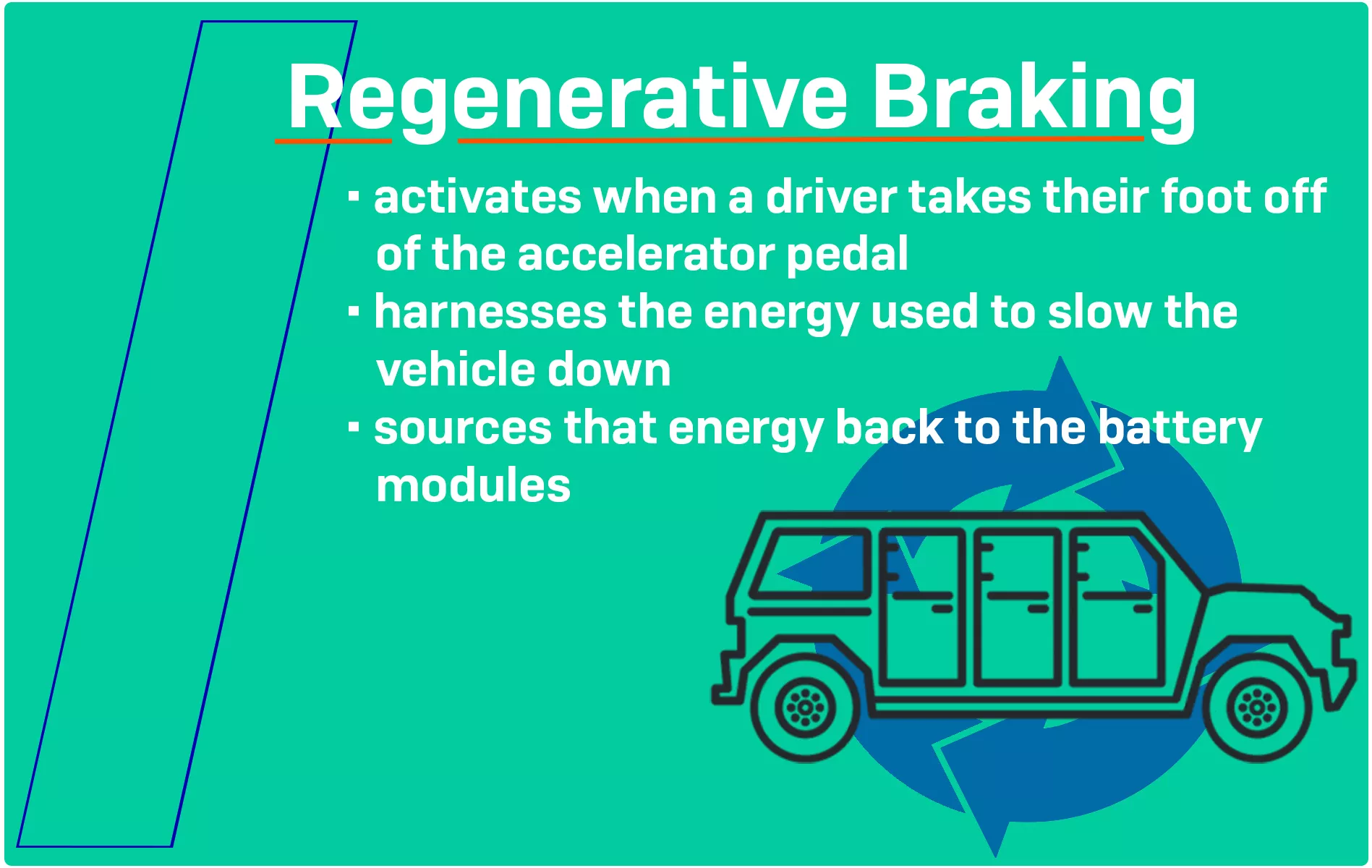

Electric vehicles have unique technology that continues to improve. One feature common across nearly all electric vehicles is the process called “regenerative braking.” Regenerative Braking activates automatically and slows the vehicle down while simultaneously sending energy back into a vehicle’s battery modules.

Friction Braking Vs. Regenerative Braking

To better understand regenerative braking, let’s first recap an internal combustion engine (ICE) vehicle’s braking process. When a driver takes their foot off the accelerator pedal in an ICE vehicle, the motor stops supplying power and the vehicle will begin to coast. Any vehicle in motion contains a significant amount of kinetic energy. Air drag, rolling resistance, and other forces will cause the vehicle’s kinetic energy to slowly dissipate, and it will eventually slow down. When a driver applies the brake pedal, the brake system applies friction to convert the vehicle’s kinetic energy to heat, quickly dissipating said energy and bringing the vehicle to a stop.

As the name suggests, an electric vehicle is driven by electric motors. Re-chargeable battery modules supply electrical energy to the motors and the motors, in turn, drive the gearbox and differential to propel the vehicle. When an EV driver presses the accelerator pedal, the electric motor rotation speed increases, and the vehicle drives faster. When the driver lets off the accelerator pedal, the vehicle’s electric motors act as generators. The motors redirect their output to source energy back into the battery modules while simultaneously creating a braking force which works to slow the vehicle to a stop.

Regenerative Braking in Rokion Trucks

A traditional, friction-based brake system is still present on all electric vehicles but, in some cases, a driver may not need to use it. In normal operating circumstances, some smaller, non-commercial EVs can be driven without ever touching the brake pedal*

When it comes to larger, industrial electric vehicles, regenerative braking on its own is not enough to stop the vehicle. The Rokion R400, whose gross vehicle weight rating ranges from 7,000 to over 10,000 kg, contains a tremendous amount of kinetic energy while in motion. In this case, the regenerative braking process works in conjunction with a traditional, friction-based brake system to dissipate the truck’s kinetic energy and stop the vehicle.

* Often this requires the driver to select a “one pedal” or “e-pedal” driving mode first. In emergency circumstances, of course, drivers should always press the brake pedal and apply the traditional brake system.

The Fundamentals of Regenerative Braking

The principle behind regenerative braking is the effective use of energy. When working to stop an internal combustion engine vehicle, a friction braking system squanders all of that vehicle’s kinetic energy. When working to stop an electric vehicle, regenerative braking harnesses the kinetic energy of the moving vehicle and sources it back to its own battery modules.